The discourse surrounding vertical farming has evolved from speculative futurism to present-day practicality, yet the conversation remains inextricably tied to one critical factor: energy. Unlike traditional agriculture, which leverages the free and abundant power of the sun, the controlled environment of a vertical farm is an energy-intensive endeavor. The very promise of these systems—maximizing yield per square foot, eliminating pesticides, and bringing production closer to urban centers—hinges on the efficient and intelligent use of electricity. Two components stand as the primary determinants of a farm's operational sustainability and economic viability: the efficiency of its LED lighting systems and the sophistication of its water recirculation infrastructure.

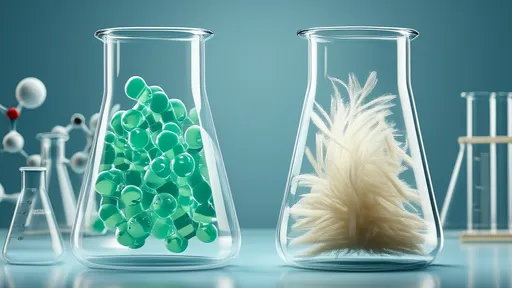

At the heart of every vertical farm is its artificial sun: the LED lighting array. The progression of Light Emitting Diode technology has been nothing short of revolutionary for the industry. Early adopters were burdened with high-intensity discharge lamps that generated excessive heat and consumed power at an unsustainable rate. The shift to LEDs was a game-changer, but not all LEDs are created equal. The key metric here is Photosynthetic Photon Efficacy (PPE), measured in micromoles of photosynthetic active radiation (PAR) per joule of electrical energy (μmol/J). It quantifies how effectively a light fixture converts watts from the wall into usable light for plant growth.

Just a few years ago, a top-tier LED fixture might have boasted a PPE of 2.0 to 2.5 μmol/J. Today, cutting-edge systems are pushing past 3.5 μmol/J, with laboratory prototypes hinting at efficiencies nearing 4.5. This incremental progress is monumental. For a large-scale facility, a 0.5 μmol/J improvement can translate to a reduction of hundreds of thousands of dollars in annual energy costs and a significantly lowered carbon footprint. However, raw efficacy is only part of the equation. The spectral quality of the light—the specific wavelengths emitted—profoundly influences plant morphology, growth rate, and nutritional content. Advanced systems now employ tunable spectra, allowing farmers to dial in precise light "recipes" for different crops and growth stages, optimizing not just for speed of growth but for quality and flavor, thereby maximizing the energy invested.

Furthermore, the integration of smart control systems has added a layer of dynamic efficiency. Lights are no longer simply turned on or off. They are dimmed based on the amount of natural light penetrating the facility, or they pulse at frequencies that can stimulate plant responses while reducing total energy consumption. The synergy between advanced semiconductor technology, data science, and plant biology is driving the LED revolution forward, making the goal of carbon-neutral food production increasingly attainable.

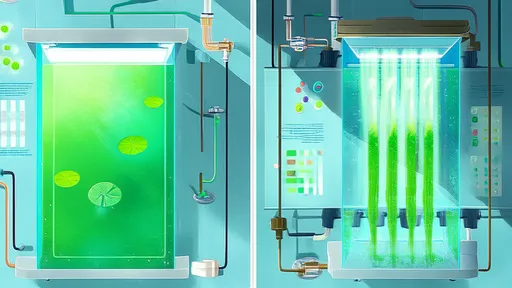

While lighting often steals the spotlight, the hidden hero of vertical farming efficiency is its water management system. Traditional open-field agriculture is notoriously thirsty, with a significant portion of water lost to evaporation, runoff, and percolation beyond the root zone. In stark contrast, a closed-loop vertical farm can recirculate over 95% of its water. This astounding conservation is its greatest strength, but the energy cost of maintaining this cycle is a critical variable in the overall efficiency ratio.

The process begins with the nutrient delivery system, typically some form of hydroponics, aquaponics, or aeroponics. Aeroponics, which mists the roots of suspended plants with a nutrient solution, is often cited as the most water-efficient method, using up to 95% less water than traditional farming. However, it is also among the most energy-intensive, requiring high-pressure pumps and precise nozzles that must operate almost continuously. Hydroponic systems, where roots are submerged in or exposed to a flowing nutrient solution, strike a more common balance between water savings and pumping energy.

The real energy burden, however, lies in the water treatment loop. Recirculated water cannot be used indefinitely. It becomes concentrated with root exudates (organic compounds released by plants), potentially harmful microbes, and imbalances in nutrient salts. To maintain a healthy root zone and prevent disease, the water must be constantly treated. This involves filtration, UV sterilization or ozonation, and recalibration of nutrient levels.

Each of these steps consumes energy. UV sterilizers require powerful lamps to kill pathogens, while ozone generators need electricity to create the O3 gas. Advanced membrane filtration systems, including reverse osmosis for removing dissolved solids, are pressure-driven and therefore power-hungry. The efficiency of a farm's water system is thus a measure of its ability to keep water in circulation for as long as possible with the minimal amount of active treatment. Innovations like passive solar water heating, energy-recovery systems in filtration, and the use of beneficial microbes to outcompete pathogens can drastically reduce the electrical load of maintaining water quality.

The true measure of a vertical farm's performance is not the efficiency of its lights or its water system in isolation, but the complex interplay between them—the holistic energy efficiency ratio. This is where operational intelligence and system integration become paramount. For instance, the waste heat generated by LED fixtures is a double-edged sword. It represents an energy loss from the lighting system, but it can be captured and used to warm the greenhouse or the nutrient solution, reducing the burden on separate HVAC systems. A farm that views its components as part of a synergistic whole, rather than isolated systems, can find these crucial efficiencies.

Data is the currency of this optimization. A modern vertical farm is a dense network of sensors monitoring everything from photon flux density at the canopy level to water temperature, pH, electrical conductivity, and dissolved oxygen in the nutrient solution. Machine learning algorithms can analyze this data in real-time, making micro-adjustments to light spectra, irrigation cycles, and nutrient dosing to find the most energy-efficient path to a successful harvest. This might mean slightly reducing light intensity during off-peak energy hours when electricity is more expensive or carbon-intensive, or altering irrigation frequency based on real-time plant transpiration rates measured by climate sensors.

The pursuit of efficiency is also driving architectural and design innovations. New facilities are being designed from the ground up to be energy-positive. This involves integrating photovoltaic panels on roofs and walls, using geothermal energy for base-load heating and cooling, and designing building layouts that maximize natural light penetration to supplement LEDs. The vertical farm is gradually evolving from a mere consumer of energy to a potential prosumer—both consuming and producing power within a local grid.

In conclusion, the future of vertical farming is irrevocably tied to its energy signature. The narrative has moved beyond simply whether these farms can work, to how they can work optimally. The relentless innovation in LED photon efficacy and the clever engineering of closed-loop water systems are steadily driving down the kilowatt-hours required per kilogram of produce. The next frontier lies in smart integration—creating farms that are not just collections of efficient parts, but intelligent, adaptive organisms in their own right. The goal is a resilient, urban-based food system that provides fresh, local produce year-round with a fraction of the land and water footprint of conventional agriculture, and a minimized, and ultimately neutral, energy footprint to match.

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025