In the realm of advanced materials science, few elements possess the captivating versatility of niobium, particularly when refined to exceptional purity. Among its many intriguing applications, one stands out for its blend of scientific precision and artistic allure: the electrolytic passivation of high-purity niobium to produce stunning, vibrant colors. This process not only showcases the metal's unique properties but also opens doors to innovative uses in art, jewelry, and technology.

Niobium, a lustrous transition metal, is often overshadowed by its more famous counterparts like titanium or tantalum. However, when purified to levels exceeding 99.9%, it reveals characteristics that make it ideal for surface treatment through electrolysis. The key lies in its ability to form a stable oxide layer when subjected to an electric current in a suitable electrolyte solution. This layer, though mere nanometers thick, interacts with light in a way that creates iridescent colors through thin-film interference.

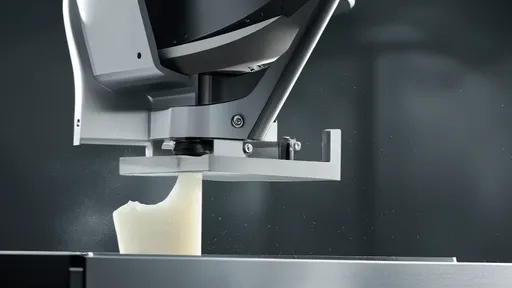

The science behind this coloration is both elegant and complex. As voltage is carefully applied during the electrolytic process, the thickness of the oxide layer grows in precise increments. Each thickness corresponds to specific wavelengths of light being reinforced or canceled out, resulting in the perception of different colors. By controlling parameters such as voltage, time, and electrolyte composition, technicians can achieve a breathtaking spectrum—from deep blues and emerald greens to radiant golds and fiery reds.

What makes high-purity niobium particularly suited for this application is its remarkable consistency and lack of impurities. Even minute contaminants can disrupt the uniform growth of the oxide layer, leading to uneven or muddy colors. Thus, the pursuit of ultra-high purity is not merely academic; it is essential for achieving the brilliant, reproducible hues that make niobium so valued in decorative and functional applications.

Beyond its aesthetic appeal, this electrolytic passivation process significantly enhances niobium's durability. The oxide layer is exceptionally hard and resistant to corrosion, making it suitable for items subjected to frequent handling or harsh environments. This combination of beauty and resilience has not gone unnoticed by artists and designers, who increasingly incorporate colored niobium into sculptures, architectural elements, and high-end jewelry.

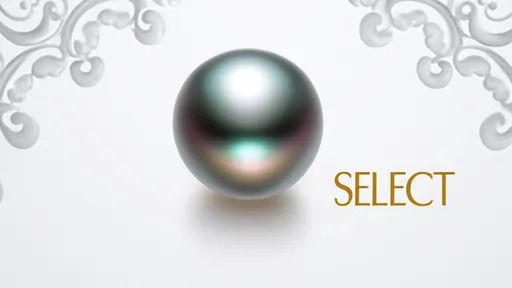

In the world of jewelry, colored niobium offers a compelling alternative to traditional precious metals and gems. Its hypoallergenic properties make it ideal for wearers with sensitive skin, while its vibrant colors—achieved without dyes or pigments—provide a unique, lasting brilliance. Artisans appreciate its workability and the ability to create custom shades through precise control of the electrolysis process, allowing for truly one-of-a-kind pieces.

The technological implications extend far beyond adornment. The same principles of electrolytic passivation are employed in the production of specialized optical components, where thin oxide films are used to create filters and coatings with specific light-interaction properties. Additionally, the corrosion-resistant oxide layer makes treated niobium valuable in aerospace and chemical processing industries, where materials must withstand extreme conditions without degrading.

Recent advancements in electrolytic techniques have pushed the boundaries of what is possible with niobium coloration. Researchers are experimenting with pulsed voltage patterns, multi-step processes, and novel electrolytes to achieve finer control over the oxide layer's properties. Some are even exploring the integration of nanostructures to create colors that shift with viewing angle or environmental conditions, adding dynamic elements to static surfaces.

Despite these exciting developments, challenges remain. Achieving absolute consistency across large surfaces or complex shapes requires precise control over current distribution and electrolyte flow. Moreover, the vibrant colors, while stable under normal conditions, can be affected by extreme heat or abrasive wear. Ongoing research aims to enhance the durability of the oxide layer without compromising its visual qualities.

Looking ahead, the intersection of art and science in niobium electrolytic passivation continues to inspire innovation. Artists collaborate with materials scientists to push creative boundaries, while engineers draw inspiration from nature's own iridescence—such as that found in butterfly wings or opals—to develop new applications. This synergy promises not only more beautiful objects but also advanced functional materials with tailored optical and surface properties.

In conclusion, the electrolytic passivation of high-purity niobium represents a fascinating convergence of materials science, electrochemistry, and aesthetic design. It transforms a relatively obscure metal into a canvas for vibrant, durable colors that captivate the eye and ignite the imagination. As techniques refine and applications expand, this process stands as a testament to human ingenuity—turning fundamental scientific principles into sources of beauty and innovation.

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025