In an era where sustainability is no longer a buzzword but a necessity, the world of design and manufacturing is undergoing a profound transformation. Among the most promising innovations emerging from this green revolution is the use of mycelium, the root structure of mushrooms, to create biodegradable and eco-friendly products. One particularly fascinating application lies in the realm of luxury and everyday items: jewelry boxes and their protective linings. This isn't just a niche experiment; it represents a significant shift towards a circular economy, challenging the very materials we have relied upon for centuries.

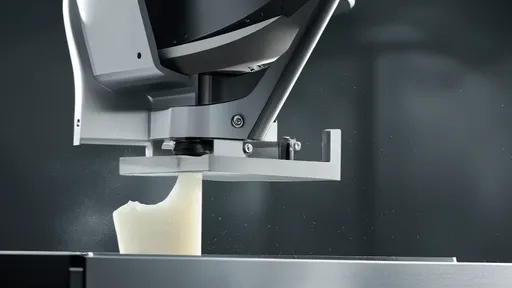

The journey begins with mycelium, a complex network of fungal threads that typically grows beneath the forest floor. Scientists and designers have harnessed its natural properties to act as a biological binder. When combined with agricultural waste like hemp hurd, oat hulls, or sawdust, mycelium can be grown into specific shapes using molds. Over a period of several days in a controlled environment, it digests the waste substrate, binding it into a solid, durable material. This process requires minimal energy, no synthetic chemicals, and results in a product that is entirely compostable at the end of its life, returning nutrients to the earth instead of languishing in a landfill.

The transition from this raw biomaterial to a refined product like a jewelry box is a testament to human ingenuity. After the growth period, the mycelium-based material is heat-treated to stop the growth process, resulting in a lightweight yet surprisingly sturdy structure reminiscent of foam or a soft wood. Artisans and manufacturers can then sand, dye, and finish these forms to achieve a desired aesthetic, from a raw, earthy texture to a smooth, lacquered surface that rivals traditional materials like velvet-lined wood or plastic. The inherent versatility of mycelium allows for the creation of intricate hinges, clasps, and compartments, making it perfectly suited for the precise world of jewelry storage.

Perhaps the most revolutionary aspect is the development of mycelium-based lining. Traditionally, jewelry box interiors rely on plastics, polyester foams, or chemically treated fabrics to cradle and protect precious items. Mycelium foam presents a stunning alternative. It can be grown to be soft, pliable, and shock-absorbent, providing a gentle, protective cushion for rings, necklaces, and watches. This bio-foam is not only effective but also inherently antimicrobial and hypoallergenic, offering a purer environment for storage without the off-gassing of volatile organic compounds (VOCs) commonly associated with synthetic foams.

The environmental argument for this shift is overwhelming. The conventional jewelry box industry, a subset of the larger packaging market, has long been a contributor to deforestation (for wood and paper pulp) and petroleum consumption (for plastics and synthetic linings). The supply chain is often long and carbon-intensive. In stark contrast, mycelium production is inherently local and low-impact. The feedstock is agricultural waste, a product that would otherwise be burned or left to decompose, releasing carbon. Mycelium production sequesters this carbon into a usable product. Furthermore, at its end-of-life, a mycelium jewelry box can be broken up and placed in a garden, where it will decompose into rich soil within a matter of months, completing a beautiful, natural cycle.

For consumers and luxury brands alike, the appeal extends beyond sustainability. There is a growing demand for products with a story, a soul, and a positive impact. A mycelium jewelry box is not merely a container; it is a conversation piece. It speaks of a commitment to innovation, environmental stewardship, and a deep respect for natural processes. Brands that adopt this technology are positioning themselves at the forefront of ethical luxury, appealing to a conscious consumer base that values transparency and responsibility. The unique, organic texture of each piece ensures that no two boxes are exactly alike, adding an element of exclusive, natural artistry.

Of course, the path forward is not without its challenges. Scaling production to meet global demand while maintaining the low-energy, artisanal quality of the process is a significant hurdle. There are also consumer perceptions to overcome; convincing a market accustomed to the weight and gloss of traditional materials that a lightweight, grown material is synonymous with luxury and durability requires education and elegant design. However, ongoing research is continuously improving the material's strength, fire resistance, and water resilience, broadening its potential applications.

In conclusion, the development of mycelium-based jewelry boxes and linings is far more than a novel eco-trend. It is a powerful symbol of a new paradigm in manufacturing—one that works in harmony with nature rather than exploiting it. It demonstrates that we do not have to choose between beauty, function, and responsibility. By turning to the humble mushroom, designers are crafting a future where the objects that hold our most treasured possessions are themselves treasures of the earth, designed to give back long after their primary job is done. This is not just the future of packaging; it is a blueprint for a more thoughtful and regenerative world.

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025