In the world of precious stone processing, the art of cutting jade has long been a delicate balance between precision and preservation. For centuries, artisans and manufacturers have grappled with the challenge of minimizing material loss during the cutting phase, where even a fraction of a millimeter can translate into significant financial and aesthetic value. Traditional methods, while steeped in craftsmanship, often resulted in substantial wastage due to the inherent limitations of blade thickness, vibration, and manual control. However, a technological revolution is quietly unfolding in workshops and factories, one that promises to redefine efficiency and sustainability in jade processing: the adoption of diamond wire saw cutting.

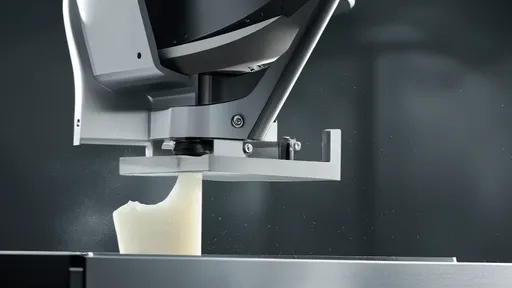

The diamond wire saw, though not an entirely new invention, has undergone significant refinements that make it particularly suited for cutting hard, brittle, and valuable materials like jade. Unlike conventional saws that use rigid blades coated with abrasive materials, diamond wire saws employ a flexible cable or wire embedded with synthetic diamond particles. This wire, often just a few hundred microns in diameter, moves at high speeds under tension, allowing it to slice through jade with astonishing accuracy and minimal kerf—the width of material removed during cutting. The result is a dramatic reduction in material loss, sometimes lowering waste rates to unprecedented single-digit percentages.

What sets diamond wire saw technology apart is its non-contact or low-contact cutting mechanism. Traditional saw blades generate heat and friction, which can cause micro-fractures, chipping, or even thermal damage to the jade, leading to further material loss during subsequent polishing stages. In contrast, the diamond wire saw produces less heat and exerts minimal lateral force on the workpiece. This is crucial for jade, a material known for its varying hardness and susceptibility to internal stresses. By reducing mechanical and thermal stress, the wire saw preserves the integrity of the jade, ensuring that more of the raw stone is transformed into usable, high-quality finished products.

The benefits extend beyond mere material savings. For jade artisans and manufacturers, the reduced loss rate translates directly into higher profitability. Jade, especially high-grade nephrite or jadeite, can be exorbitantly expensive, and every gram saved is a gram earned. Moreover, the precision of diamond wire saws allows for more intricate and customized cuts, enabling designers to explore complex shapes and thin sections that were previously too risky or wasteful to attempt. This opens up new creative possibilities in jewelry and art, where uniqueness and detail command premium prices.

From an environmental perspective, the adoption of diamond wire saws aligns with growing industry demands for sustainability. Lower material waste means less extraction of raw jade, which is often sourced through mining operations that can have ecological impacts. Additionally, the efficiency of wire saws can lead to reduced energy consumption compared to traditional methods, as they often require less power to operate and complete cuts faster. Some advanced systems even incorporate recycling mechanisms for the coolant and abrasive slurry, further minimizing their environmental footprint.

Despite its advantages, the transition to diamond wire saw technology is not without challenges. The initial investment in equipment can be higher than that for traditional saws, and operators may require specialized training to handle the machinery and optimize cutting parameters. However, many in the industry view these costs as worthwhile long-term investments. As technology continues to advance, we are seeing more user-friendly and automated systems enter the market, making the technology accessible to smaller workshops and not just large-scale operations.

Looking ahead, the integration of digital technologies with diamond wire saws promises even greater precision and efficiency. Computer numerical control (CNC) systems can be paired with wire saws to execute pre-programmed cuts with microscopic accuracy, reducing human error and variability. Real-time monitoring sensors can adjust tension, speed, and cooling during the cutting process to adapt to the jade's specific characteristics, such as veins or inclusions. These smart systems are pushing the boundaries of what's possible, ensuring that material loss approaches theoretical minimums.

In conclusion, diamond wire saw cutting represents a paradigm shift in jade processing, offering a blend of precision, efficiency, and sustainability that traditional methods cannot match. By slashing loss rates to new lows, it not only enhances economic returns but also supports artistic innovation and environmental responsibility. As this technology becomes more widespread and refined, it is poised to become the new standard in the industry, ensuring that the ancient beauty of jade is preserved and celebrated with modern ingenuity.

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025